Our Services

Post Processing

Post-processing is crucial in additive manufacturing for refining 3D-printed parts. Techniques like surface finishing, heat treatment, and precision machining enhance aesthetics and function while reducing waste by efficiently removing support structures. The importance of post-processing for high-quality components is evident as additive manufacturing evolves.

Machining

ADDME: Your one-stop solution for additive manufacturing and high-quality machining services.

Seamlessly integrating 3D printing with precision machining for comprehensive solutions. We specialize in crafting intricate, highly precise parts with exceptional surface finishes, ensuring reliable results and short cycle times.

Heat Treatment

We enhance mechanical properties in 3D-printed metal parts through heat treatment. Our customized services tailor the process to specific materials and applications, aiming to deliver high-quality, fully functional 3D-printed parts that exceed expectations.

Hot Isostatic Pressing (HIP)

Hot Isostatic Pressing (HIP) is a post-processing method that improves the mechanical properties of 3D printed parts by subjecting them to high temperature and pressure, eliminating defects to create dense and strong components. Our company provides HIP services to enhance the quality and performance of 3D printed parts for our customers.

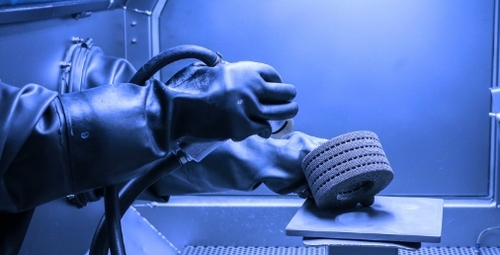

Surface Treatment

We provide a variety of surface treatment services in additive manufacturing to enhance the functionality, durability, and aesthetics of 3D-printed parts. Surface treatment includes sandblasting, polishing, painting, anodizing, etc. Our experienced team collaborates with clients to select the ideal treatment for their application, ensuring high-quality, customized results, whether for cosmetic appeal, corrosion resistance, or improved mechanical properties.

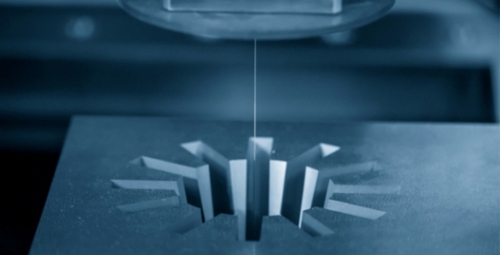

Electrical Discharge Machining

Electrical Discharge Machining (EDM) is a precise manufacturing method that removes material using electrical discharges. EDM is crucial in aerospace, medical, and automotive industries for tasks like tooling and turbine blade production. It's also valuable in additive manufacturing for precise part removal from the build plate.